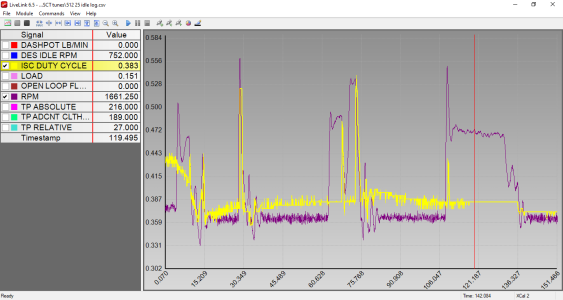

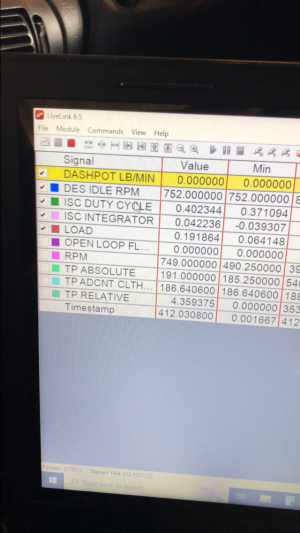

Ok guys I need serious spoon feeding, tuning has never been my strongsuit but I generally learn enough to be dangerous with some direction if it’s explained to me like I’m a toddler. I’ve been datalogging and “tuning”( guessing and checking) to tame this condition but this is the best I got it and it’s still taking manual intervention to keep it from stalling after a very mild rev. It actually idles pretty good once it’s stabilized and in my datalog of this event the ISC duty cycle hovered around .35-.38ish.

This makes me think I should be focusing on Dashpot but I’m having an extremely difficult understanding it even with SCTs help sections and forum input (which has become incredibly limited by SCTs nuking of the Pro racer forum, EECtuning being down and Decipha’s site/forum speaking a completely different language from SCT).

Anyway, you tell me, in this vid I saved it from stalling every time it dipped to near 500rpm and at some point you can see how it stabilizes to the commanded 750 rpm. Even just a hint on what to log and what to mess with and what not to mess with in PRP would be helpful. Right now I’m in over my head

This makes me think I should be focusing on Dashpot but I’m having an extremely difficult understanding it even with SCTs help sections and forum input (which has become incredibly limited by SCTs nuking of the Pro racer forum, EECtuning being down and Decipha’s site/forum speaking a completely different language from SCT).

Anyway, you tell me, in this vid I saved it from stalling every time it dipped to near 500rpm and at some point you can see how it stabilizes to the commanded 750 rpm. Even just a hint on what to log and what to mess with and what not to mess with in PRP would be helpful. Right now I’m in over my head