- Joined

- Oct 2, 2023

- Messages

- 1,405

- Location

- New Mexico

- Vehicle Details

- 1994 Mercury Cougar XR7, 3.8L, all stock

When re-assembling the stator and bushings, here are some tips I came across.

1. Make sure the stator and bushings are clean. The can get greasy over time. I used brake cleaner.

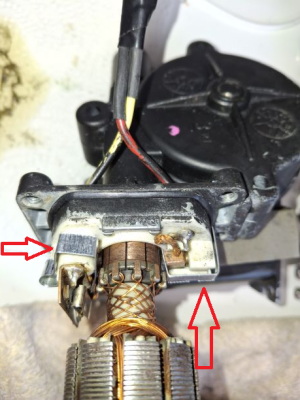

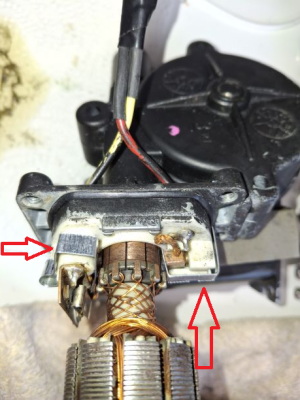

2. Find some sheet metal to make a couple braces/clips -whatever its called. I used hanger strap and cut the sides off to make a solid 3/8" piece (see pics).

3. Put the bushing spring and bushing in the side that has the contact side of the gear housing (see pic). Hold it in place while you apply the bracket.

4. Insert the other spring and bracket and put a clip over it to hold it in place as well.

5. Put the stater in the gear housing.

6. Remove the clips slowly to endure the bushings set against the stator commuter.

7. Place the motor case (magnets) over the stator slowly while holding the stator in place against the gear assembly housing. Make sure the stator goes into the housing as the magnets are VERY Strong and it will not go in the case easily.

The rest is the same way it came apart.

1. Make sure the stator and bushings are clean. The can get greasy over time. I used brake cleaner.

2. Find some sheet metal to make a couple braces/clips -whatever its called. I used hanger strap and cut the sides off to make a solid 3/8" piece (see pics).

3. Put the bushing spring and bushing in the side that has the contact side of the gear housing (see pic). Hold it in place while you apply the bracket.

4. Insert the other spring and bracket and put a clip over it to hold it in place as well.

5. Put the stater in the gear housing.

6. Remove the clips slowly to endure the bushings set against the stator commuter.

7. Place the motor case (magnets) over the stator slowly while holding the stator in place against the gear assembly housing. Make sure the stator goes into the housing as the magnets are VERY Strong and it will not go in the case easily.

The rest is the same way it came apart.