- Joined

- Sep 12, 2023

- Messages

- 2,506

- Location

- North Ridgeville, OH

- Cars in Garage

- 2

- Vehicle Details

- 1997 Thunderbird 4.6, 1998 Mark VIII LSC

Neon Light General Questions

(1997 and 1998 Generation II tail light assembly)

P/N F7LY 13A565 AAA thru AAF

(1997 and 1998 Generation II tail light assembly)

P/N F7LY 13A565 AAA thru AAF

Moisture (impurities) is the number one reason for the inverter (ballast) to fail. For reliability reasons, all moisture must be removed before any inverter is replaced.

Each inverter (ballast) has two circuits, one to start the neon glow and the other to maintain the glow. Because of the internal circuitry, the ballast can not be tested like one would think.

As long as there is power and ground going to the inverter and the neon bulb is not broken (glass shards inside the light housing), in most cases a new inverter will solve the problem.

There is a wire mesh and ground screw for the inverter; this ground is for EMI purposes (radio interference). It has no effect on the neon's operation other than shorting the inverter if water is inside the housing (it has been found to be most desirable to disconnect and insulate the wire mesh from any metal structure or ground).

There are two fuses in the system. Fuse #31 is for the parking lights and fuse #32 is for the brake lights. If you are experiencing symptoms similar to item #8 below, check both fuses.

****

Ask yourself the following questions to help determine your light condition.

1. What area of the country do you live in? Does it rain often?

2. Is there water or moisture inside the light? It may be best to add drain/vent holes.

3. Does the neon bulb flash at all when brakes are applied? This could be a bad connection or a sign of an inverter gone bad.

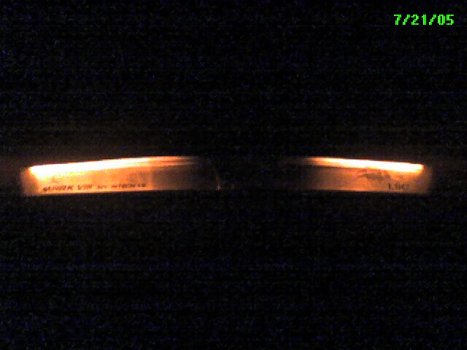

4. Do you see a glow from just the bulb ends when the parking lights or brakes are on (see photos)? This is a sign of an inverter that has gone bad.

5. Behind the trunk lid cover is the inverter input connector (three wire). Do you have power and ground? At least 9.5v is needed to power the inverter.

6. Does the reflector have what looks like mold or black lines inside (see photo)? This is a sign of moisture - recommend adding drain/vent holes.

7. Do you see any glass inside the light? If so, does the glass look cylindrical in shape? This may be a broken bulb, which requires opening the housing to replace the lamp.

To test the bulb, have a local neon shop hook up one of their inverters while the light is on the bench. Most shops have inverters that put out 2000-5000v with variable current. This device is perfect for testing the bulb. Alternate method: Most neon shop also have a high voltage wand. This wand can be used if the bulb has been removed from the housing. Check with your local neon shop to see of they can help.

8. If your tail light fuses are blowing, disconnect the inverter connector and replace the fuses. Do your other brake/tail lights now work normally? If so, This is a sign that your inverter has gone bad.

9. Does your light have issues with cooler temperatures, or maybe the neon just stops working when the temperature drops? This is a sign that the inverter (ballast) has been weakened or damaged.

10. Is your light intermittent or flickering? Check the condition of the wires that run down the trunk lid arm. Also check the male slide pins at the inverter connector. These pins have been found corroded and needing to be cleaned and/or re-tinned.

As a set of best practices, consider the following:

Disconnect the wire mesh for the base plate

Protect the mesh from coming in contact with any metal structure (or cut the mesh metal off)

Extract the pins from the three wire (ballast) connector

Scotch-brite the pins

Re-tin the pins with a light coating of solder

Without the outer plastic connector, plug the male pin into the other connector half.

Does the neon work normally?

If it does, re-assemble the connector

If it does not work, proceed to step #12 below

NOTE: Tarnish is what I have found to be building up on the contact surface; preventing electrons from flowing from the female pins to the male pins. This is why I mention re-tinning the male pins.

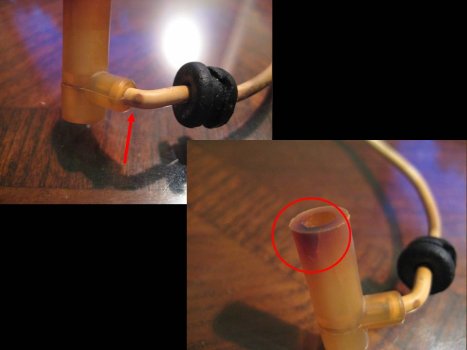

11. Internal shorts are not normally seem unless you separate the housing to gain access to the bulb ends. I can not say that all ballasts are damaged by internal shorts. However there are only two ways that damage them - shorts and heat. A short would look something like this:

12. Think about doing the following steps before replacing another inverter.

Without cutting the housing open, the following steps can be taken to prevent arcing from the input (GTO) wires.

Pull the rubber gourmet out

Use a ¼ inch cutoff wheel to trim into the housing around the base (see photo)

Pull the excess of the GTO wire out

Put a small amount of silicone caulking in and around the boot

Glue the hole closed

Tape over area to act like a water shield

Using electrical tape; tape a 4x12 inch section of the trunk lid in the area where the GTO wires pass through the light housing (from the edges, inward)

Use two additional (6 to 8 inch) sections of GTO sleeve; cut a 1/4 inch wide 1/2 inch deep notches in one end.

With the notched end first; slide the sleeve over the section of GTO wire that enters the housing. Make sure the GTO sleeve overlaps the rubber grommet area.

Now you’re ready to replace the inverter.

****

I have noted four failure symptoms for the inverters.

1. Dead inverter, does nothing

2. Internal short that blows fuses

3. Damaged internal circuit; bulb glows but does not fully light

4. Light housing that shorts the inverter to ground (moisture inside)

Out of the four, #2 is on the rise. Given there is no condition to see #4, a simple inverter replacement will have your neon working again. As for #4, this is why I ask if the neon light can be bench checked. If too much current drain is noted from the lamp, a replacement inverter will be damaged. High current can only be fixed if the housing is opened up. (Requires cutting)

***