- Joined

- Oct 2, 2023

- Messages

- 1,581

- Location

- New Mexico

- Cars in Garage

- 1

- Vehicle Details

- 1994 Mercury Cougar XR7, 3.8L, all stock

Today's topic: "Have you used an Oxy / Propylene or Propane torch with any success?

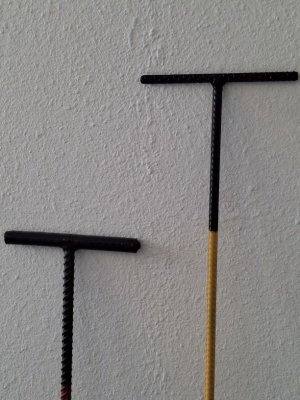

I was making a new valve wrench for my water shut off valve. Using 3ft long rebar, I flux welded the T for a handle and cut a piece of 5/16" thick chain link in half to use as the end of the wrench. Turns out it was a bit small and did not fit over the valve. I have an oxy / propane torch set (inherited), but need the gasses and was thinking of heating the 5/16" chain piece and bending it open some.

I even thought of using the torch to weld some items when the flux welder won't do the job. I read some articles about the oxy / prop torch and it seems to have mixed reviews as to what it can do.

So, before I buy the gasses, I thought I would see what you all's experience with the torch might be.

Thanks!

I was making a new valve wrench for my water shut off valve. Using 3ft long rebar, I flux welded the T for a handle and cut a piece of 5/16" thick chain link in half to use as the end of the wrench. Turns out it was a bit small and did not fit over the valve. I have an oxy / propane torch set (inherited), but need the gasses and was thinking of heating the 5/16" chain piece and bending it open some.

I even thought of using the torch to weld some items when the flux welder won't do the job. I read some articles about the oxy / prop torch and it seems to have mixed reviews as to what it can do.

So, before I buy the gasses, I thought I would see what you all's experience with the torch might be.

Thanks!