CDsDontBurn

PostWhore

I know some of us here have been talking about doing a 3D scan and print of our plastics, namely the cluster and radio bezels, for the last few years, and it looks like there's someone who is dedicated to doing just this!

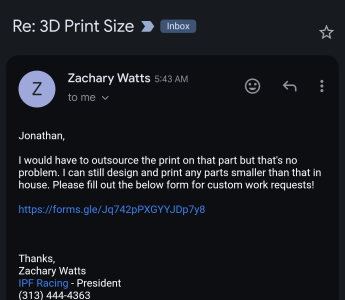

My wife found the guy on FB and forwarded me his page and after watching some of his videos, he seems to do good stuff! He has a Google Doc sheet for taking orders.

I'm definitely going to check him out for replacement bezels.

www.facebook.com

www.facebook.com

My wife found the guy on FB and forwarded me his page and after watching some of his videos, he seems to do good stuff! He has a Google Doc sheet for taking orders.

I'm definitely going to check him out for replacement bezels.

Log into Facebook

Log into Facebook to start sharing and connecting with your friends, family, and people you know.

www.facebook.com

www.facebook.com