- Joined

- Sep 22, 2023

- Messages

- 951

- Location

- Las Vegas

- Vehicle Details

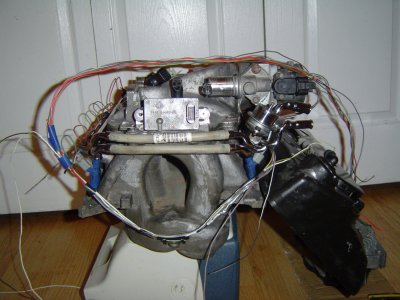

- 1995 Ford Thunderbird LX No Engine No Trans

Believe me I get it! My son did the same thing. Started out as "just a paint job and some other stuff"...Much appreciated! If it wasn't my first car, I'm sure I'd have moved on. Too much time and money invested at this point to quit!