MadMikeyL

Administrator

Some of us change the the stock filters to the K&N filters which require oiling. But if you put too much oil onto the filter, some of that oil gets stuck on the MAF sensor wires, which can skew the readings and cause error codes, a check engine light, poor fuel economy, reduced performance, or even detonation and engine damage due to a lean condition. Even without an over-oiled K&N filter, dirt and grime can get through the stock paper filter if it is not changed frequently enough and cause the same problems.

But don't worry, you don't have to replace your MAF unit when that happens. They only require cleaning. But how do you clean it?

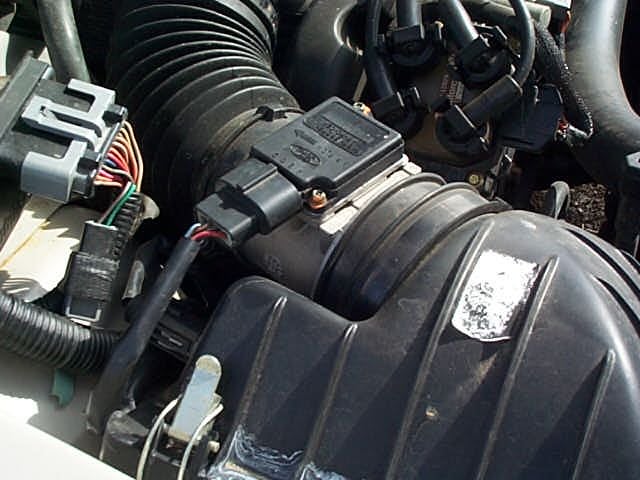

Picture one shows the location of the MAF sensor and housing directly behind the air box.

But don't worry, you don't have to replace your MAF unit when that happens. They only require cleaning. But how do you clean it?

Picture one shows the location of the MAF sensor and housing directly behind the air box.

- Unhook the wiring harness from the MAF. You will need a T-20 tamper proof torx bit to remove the 2 screws. If the sensor has become contaminated enough to cause a check engine light or drivability issues, then you should clear the codes if you have a code reader, or if not, disconnect your battery and leave it disconnected while doing this work. That will clear the codes and reset the adaptive values so that it will learn the correct fueling once the sensor is cleaned.

- Carefully remove the sensor from the housing; you will see the small sensor elements shown in picture two.

- Try to avoid using solvents that leave residues like the aromatics [toluene, xylene]. Use electrical parts cleaner or brakleen.

- Whatever you do, DO NOT TOUCH THE WIRES WITH ANYTHING! Some people have suggested using a q-tip, however the wires are very thin, and can very easily break if poked or pulled on with something, even a q-tip. If you break a wire, you are buying a new MAF. However cleaning can be accomplished without direct physical contact with the wires, so no need to risk it. Using electrical contact cleaner or brakleen, spray the sensor wires thoroughly. Immediately after spraying with the cleaner, dry them off by spraying them with compressed air. If you don't have an air compressor, you can buy canned air and most office supply stores, since it is often used to clean dust out of computer components. By spraying the air on the surface while it is still wet with cleaner, it will help remove all residue of any contaminants without touching the wires and risking damage.

- Once the MAF sensor is clean, apply a small amount of grease or petroleum jelly to the O-ring, then re-insert the sensor into the housing. Apply a small amount of anti-seize to the threads on the screws and snug them down. No need to be too tight, just enough to hold it flush with the surface. Re-connect your electrical connector, and re-connect the battery if you disconnected it in step one.