- Joined

- Sep 12, 2023

- Messages

- 5,076

- Location

- Roselle, IL

- Cars in Garage

- 1

- Vehicle Details

- 1994 Cougar XR7 DOHC TR3650

Written by cougarcragar

For those of you who have erratic turn signal operation, such as extended delay, non-functional hazard signals and drop-outs in flashing, you may consider taking apart your multi-function switch to clean the contacts.

Over the years, the copper terminals inside the switch will generate corrosion which blocks conductivity. It shows itself as green goo, which is the corrosion mixed with the ancient dielectric grease. Your mission, should you choose to accept it, is to remove the goo and apply fresh grease.

There have been countless threads started regarding this exact issue, so I hope this will serve as a reference. I hope it will allow members to restore the operation of the signals without spending the money on a new switch.

First things first: disconnect the battery before working around the steering column. Remember, the airbag is an explosive device and you will be right in front of it while noodling around in the steering column.

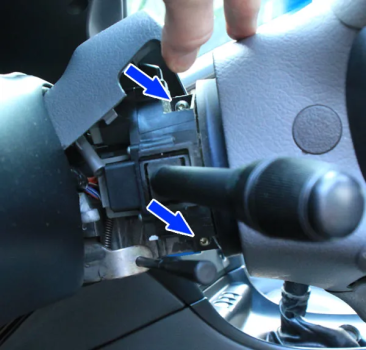

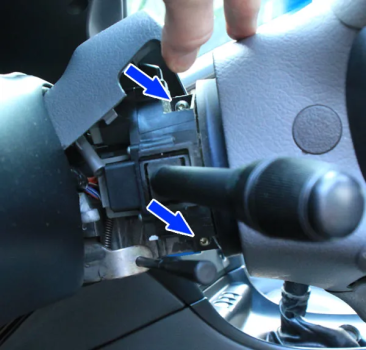

To remove the switch on my car (1996 Cougar), I removed the lower dash piece followed by the lower steering column trim. From here, you can gain access to the Torx bolts that hold the switch to the column.

With some careful movements, you can disconnect the two plugs from the switch and remove it from the column. If you first remove the gauge surround and upper column trim, it would make the process much easier. I was in a rush.

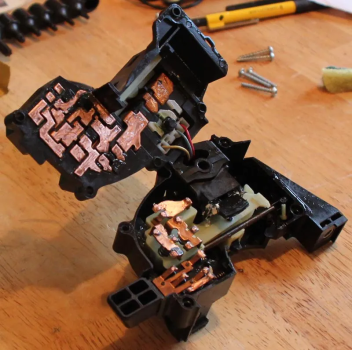

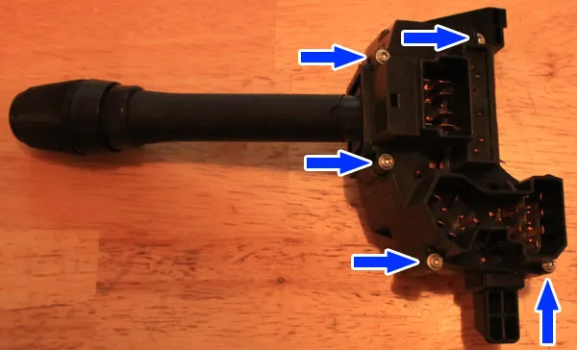

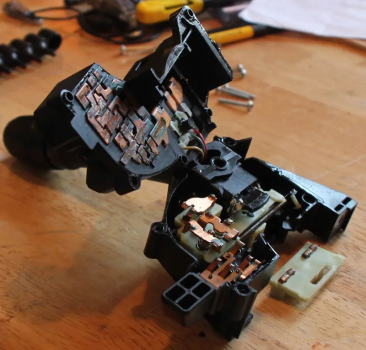

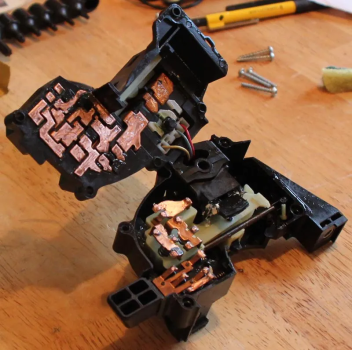

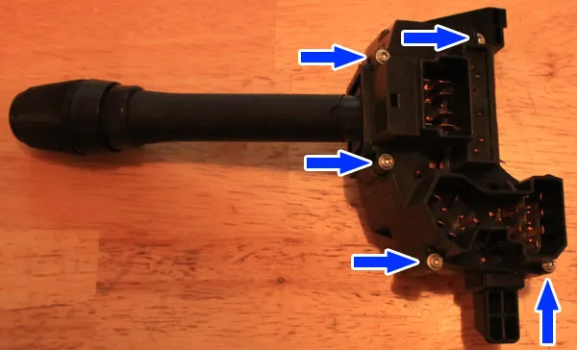

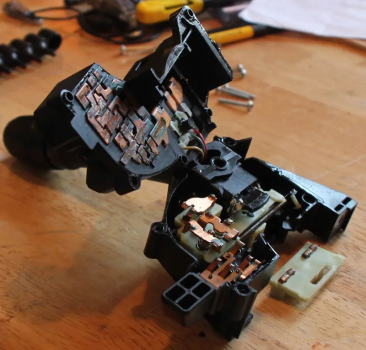

Once you have removed the switch, you can then remove the five Torx bolts (T-10) that hold the assembly together. Separate the two halves slowly and carefully, as pieces may fall out, primarily the floating pawl with the two contacts on it.

Spend some time studying the switch to see how it's assembled before digging in. Handle it carefully and slowly, as the lever mechanism is now free to pop out of the housing and you will have to reassemble.

I simply go over the contacts with some q-tips and solvent to remove the excess grease and corrosion, then I go over it with very small pieces of 1500 grit sandpaper.

Once that task is complete, I apply a quality dielectric grease and carefully reassemble. Total time for me is two hours.

For those of you who have erratic turn signal operation, such as extended delay, non-functional hazard signals and drop-outs in flashing, you may consider taking apart your multi-function switch to clean the contacts.

Over the years, the copper terminals inside the switch will generate corrosion which blocks conductivity. It shows itself as green goo, which is the corrosion mixed with the ancient dielectric grease. Your mission, should you choose to accept it, is to remove the goo and apply fresh grease.

There have been countless threads started regarding this exact issue, so I hope this will serve as a reference. I hope it will allow members to restore the operation of the signals without spending the money on a new switch.

First things first: disconnect the battery before working around the steering column. Remember, the airbag is an explosive device and you will be right in front of it while noodling around in the steering column.

To remove the switch on my car (1996 Cougar), I removed the lower dash piece followed by the lower steering column trim. From here, you can gain access to the Torx bolts that hold the switch to the column.

With some careful movements, you can disconnect the two plugs from the switch and remove it from the column. If you first remove the gauge surround and upper column trim, it would make the process much easier. I was in a rush.

Once you have removed the switch, you can then remove the five Torx bolts (T-10) that hold the assembly together. Separate the two halves slowly and carefully, as pieces may fall out, primarily the floating pawl with the two contacts on it.

Spend some time studying the switch to see how it's assembled before digging in. Handle it carefully and slowly, as the lever mechanism is now free to pop out of the housing and you will have to reassemble.

I simply go over the contacts with some q-tips and solvent to remove the excess grease and corrosion, then I go over it with very small pieces of 1500 grit sandpaper.

Once that task is complete, I apply a quality dielectric grease and carefully reassemble. Total time for me is two hours.