- Joined

- Sep 12, 2023

- Messages

- 2,506

- Location

- North Ridgeville, OH

- Cars in Garage

- 2

- Vehicle Details

- 1997 Thunderbird 4.6, 1998 Mark VIII LSC

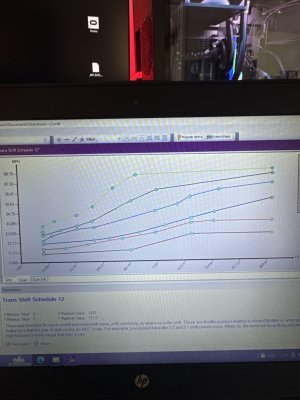

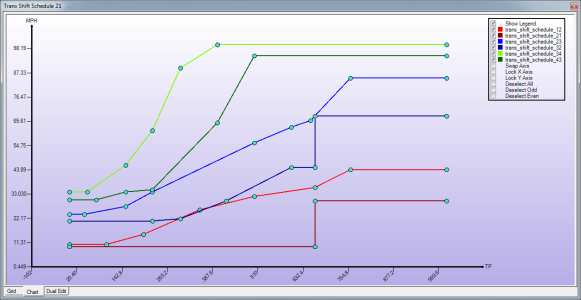

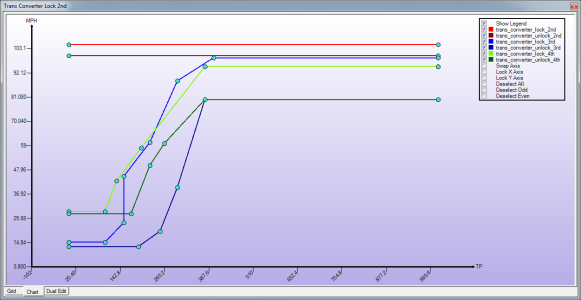

TP relative. 140 is 14%. 1000 is 100%. 0 is 0%.

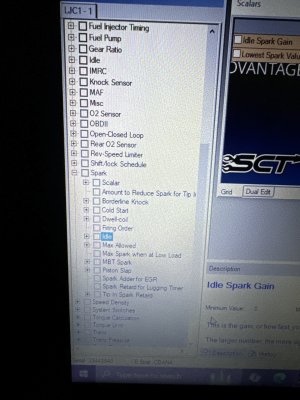

Is this with a stock 4r70w or with one that has the JMod done to it?Adjusting the behavior of the stock 4R70W is somewhat limited, but you can tweak the converter behavior and adjust the shift/lockup points to your liking. Try to avoid going too crazy with adjusting pressures - there's only so much the tune can do within the confines of the physical characteristics of the hydraulic design of the trans. Some things shouldn't be messed with unless supporting adjustments to the trans have been made.

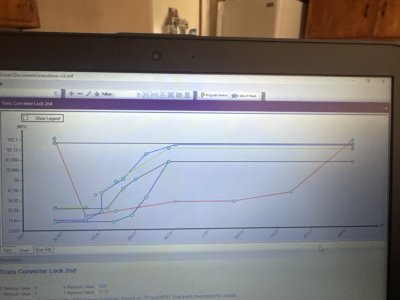

The shift (up or down) or lock/unlock event occurs when the shift line is crossed. This can happen as MPH changes, or TP changes. You need to be mindful of what you're looking at - an upshift, a downshift, a lockup, or an unlock. They function differently.

In the case of an upshift (e.g. 1-2), the shift occurs as you cross from below the line to above the line. This happens naturally as VS increases with TP remaining constant, or if VSS remains constant or TP decreases. If your shifts happen too soon, you increase the VS and/or TP to increase the area under the curve.

In the case of a downshift (e.g. a 2-1) the shift occurs when you cross from above the line to below the line. This happens naturally as VS decreases and TP remains constant, or if TP increases and VS remains constant. If you want it to be easier to trigger a downshift, you increase the VS and/or TP to increase the area under the curve.

I don't typically tune the shift/lockup characteristics with the graphs. I use the charts and adjust from there based on my desires after a drive. If I notice I'm going XX MPH and I wanted it to shift sooner (or later, or downshift, whatever) I make a mental note of that then check the schedule and adjust accordingly at that MPH

Quick question guys, when pi swapping and adding the vortech should I swap the torque converter?? I heard it sucks and ballon’s at high rpm

@XR7-4.6 thanks for the answer, I was pretty sure this sucker wouldn’t hang with the big dogs. So pretty much any 4r70w from the junkyard those years would work??