Grog6

Moderator

- Joined

- Sep 22, 2023

- Messages

- 4,240

- Location

- Harriman, TN

- Vehicle Details

- 2x 1996 Cougars, 1997 Tbird 4.6's all.

I'm pretty sure that's a 24# injector in the pic; That's the problem. it should be a 19#.

What I was trying to convey is that in my research, if you look up "1994 ford 3.8l injector" you get a host of injectors that are supposed to work. The ones mentioned above were from Summit for this engine. This is why I am looking into what injector was supposed to be on this car. From all the research I did, the injectors I pulled from the junkyard 94 Cougar where correct for that year up to 95 and some said 97. The data is very inconsistent in trying to find information on the original injector used. The numbers I pulled for the OEM injectors for the 94 Cougar are from the Denso 195500-2630 injector which is supposed to be a duplicate of the Ford F3DZ-9F593 injector. If I could find stats on the F3DZ-9F593 injector, I suspect the stats would be different, including the lb/hr. It would be fair to say it might be 19lbs as Grog said. I suspect the Denso model is 24lbs. Like I said, very inconsistent information on this subject. Finding information on the internet seems to have been over shadowed by selling ads.Only the Gen 1 SC (89-93) used 30# and the Gen 2 (94/95) used 36#. You will not find these on any factory NA 3.8.

Correct me if I am wrong - but I think the 24# were used on the Splitport 3.8s .. so that would leave the 19# and 14# .. the 14# would be more along the lines of a pre-89 3.8L.

I feel that way about eBay.I don't trust Amazon for much of anything. I sure wouldn't trust their vehicle fitment guide for parts.

You could also test the coolant temp sensor. Also, just because the engine runs like garb with the MAF unplugged doesn't necessarily mean it is sending good data to the ECU when it is plugged in. Unfortunately it isn't real easy to test/diagnose on your car.

I need to check several things today to see why it won't start.Wait. If it won't start, how can you say you fixed it?

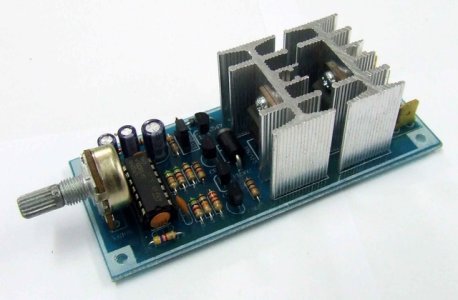

Iused a cheap pwm board I got from Oscar as part of the 200a mitsu alternator project; so far, all I've managed is to boil a battery to death .What voltage would you pulse with? Probably wouldn’t be a bad idea to use a current limiting resistor either, thoughts?

i uze 12v, and vary the pulse as high as 85%.

i uze 12v, and vary the pulse as high as 85%.