First off, I'm working on my 95 4.6. Apparently I de-torqued all my main bearing caps in preparation for looking at all the bearings. I only needed to pull one to see that they were perfect. Now I have to reinstall but I learned that they are Torque To Yield screws and I can't seem to find any except from the dealer and they are almost $20 each, which I'm certainly not willing to pay. Anybody know of another source for these? I can't even find a part number and I've already ordered (4) each that weren't correct. Seems like I can find ARP stuff all over the place but I really wanted screws, not studs...

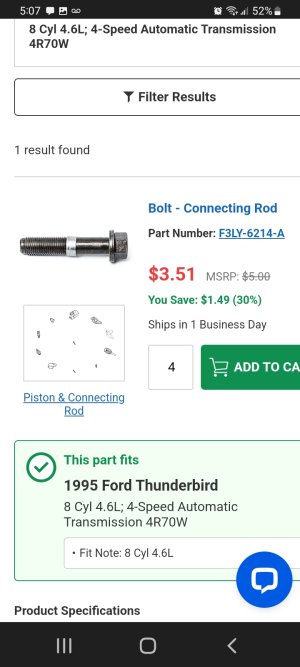

Also, I guess I did the same to the rod cap bolts and need a set of them as well.

I know the 95 was an early 4.6 and improvements have been made to the engine over time, but main and rod cap bolts? Seems like they would be the same.

Any help would be appreciated.

Also, I guess I did the same to the rod cap bolts and need a set of them as well.

I know the 95 was an early 4.6 and improvements have been made to the engine over time, but main and rod cap bolts? Seems like they would be the same.

Any help would be appreciated.