- Joined

- Sep 22, 2023

- Messages

- 951

- Location

- Las Vegas

- Vehicle Details

- 1995 Ford Thunderbird LX No Engine No Trans

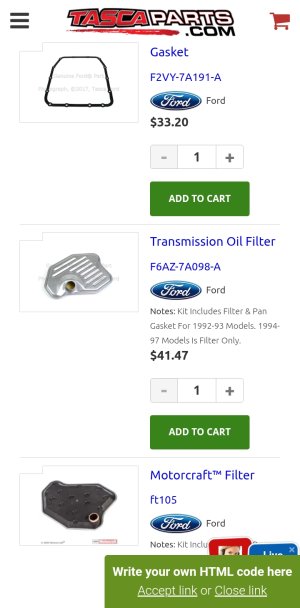

Ole SuperGordo is going to chime in. I even zoomed the picture in. That is a cork trans pan gasket. Get rid of that. Problem number one! Best to get the OEM reuseable pan gasket. The cork doesn't torque down well. I agree with Grog on the Dorman pan with the drain plug. It COULD be the manual shaft seal. You may as well do the pan gasket first. You can replace the manual shaft seal from the outside by removing the neutral safety switch. So you can eliminate the pan gasket first.

If you cannot source a proper pan gasket send me a message and I can help you find one. Ford should still sell them. There are ways to get them from autozone. Or in a pinch I can send you one. But I am NOT amazon... I can be slow.

The only 4r70w torque converter seal I saw leak was because a pump bushing came loose and moved forward and opened the converter seal up.

If you cannot source a proper pan gasket send me a message and I can help you find one. Ford should still sell them. There are ways to get them from autozone. Or in a pinch I can send you one. But I am NOT amazon... I can be slow.

The only 4r70w torque converter seal I saw leak was because a pump bushing came loose and moved forward and opened the converter seal up.