- Joined

- Oct 2, 2023

- Messages

- 1,578

- Location

- New Mexico

- Cars in Garage

- 1

- Vehicle Details

- 1994 Mercury Cougar XR7, 3.8L, all stock

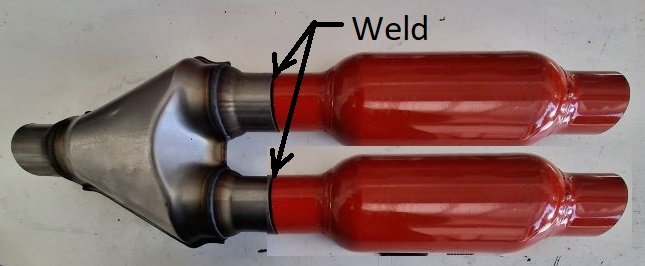

Thanks for the tip Grog, always appreciated.Just don't buy 14"mufflers for the back, lol. My shop asked me "where do you want us to put these? The right ones are ~7", lol

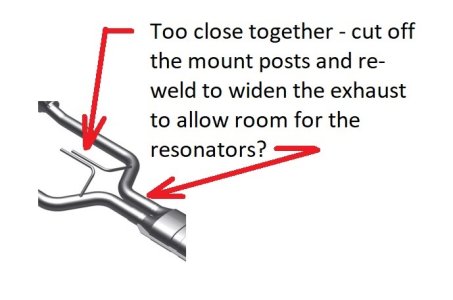

Been working on the hitch for the Town Car. I got it all installed, then found out it was too low and scraped the driveway getting out. Had to back out in an angle. Pulled it out last night and will be chopping off some metal to make it mount higher.

I really need to get a mig welder from Harbor Freight. Something to practice with and then make my own hitch and do my exhaust.