@XR7-4.6 was the tuning with the cams really crazy?? I tuned my boosted bird but didn’t have to worry about cams in the mix, any pointers?

@Grog6 that’s too much haha we’re lucky the computer does all the work for use.

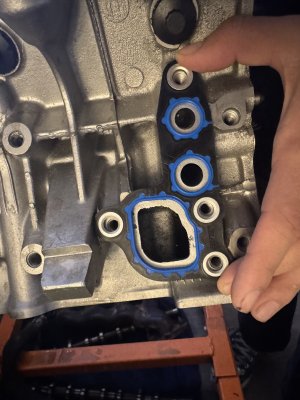

Just installed the accufab 8mm pivot pins into the block, a lil nerve racking trying to get the tap nice and Str8 but honestly it was pretty str8 forward.

Tomorrow I’m picking up the internals and hopefully assembling the short block, going to set the end gaps to 22 top ring and 26 bottom ring, I’m kinda leaning to 24 bottom but I heard it’s good to have the bottom one bigger.

@Grog6 that’s too much haha we’re lucky the computer does all the work for use.

Just installed the accufab 8mm pivot pins into the block, a lil nerve racking trying to get the tap nice and Str8 but honestly it was pretty str8 forward.

Tomorrow I’m picking up the internals and hopefully assembling the short block, going to set the end gaps to 22 top ring and 26 bottom ring, I’m kinda leaning to 24 bottom but I heard it’s good to have the bottom one bigger.