- Joined

- Sep 12, 2023

- Messages

- 5,003

- Location

- Roselle, IL

- Cars in Garage

- 1

- Vehicle Details

- 1994 Cougar XR7 DOHC TR3650

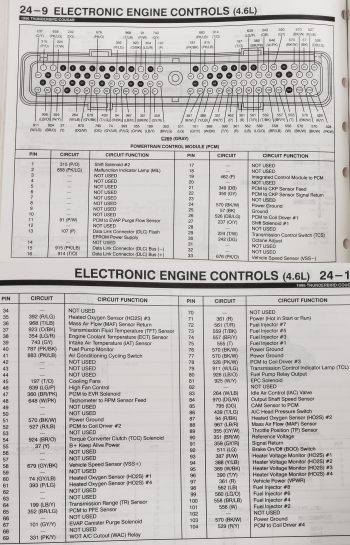

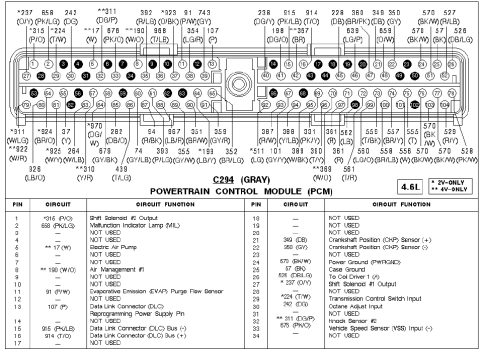

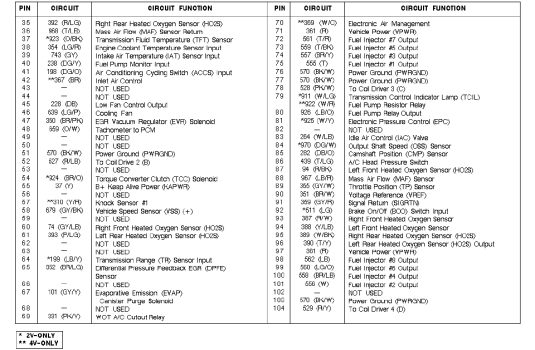

Its from a 97, 96 date code, catch code is zxa4. Cant really send it back, private purchase deal, could resale it. FB group is claiming mustang and mn-12 have different pinouts. I guess it was worth a shot... suppose i better get my chip down to the post office.

FB isn't great tech support. All that's different as you can see are unlused outputs like for the Cobra air pump, but the actual pinout is the same, as they would be both are the same physical CDAN4 hardware.