Alright so I mentioned I had plans for the factory cluster temp and oil gauges now that the autometer senders have stolen their places… well here’s the half satisfying result…

Looks like I demodded the oil gauge to function like stock pointing toward the middle right? Well I kinda did. But notice the engine is not running! Did I cheat and simply snip the resistor jumper and run the connector to ground?

Nope I did something ludicrously complicated, making what was from the factory effectively a dummy light shaped like a gauge a DIFFERENT dummy light shaped like a gauge…

The heretofore unused oil level switch on my mark pan! Hey the gauge just says OIL, it doesn’t explicitly say pressure!

So simple enough right? Well… there’s a problem or several. First off the factory “analog” oil pressure switch is a normally open switch… eg you have no oil pressure the gauge reads 0 and the switch it open you’re having a bad time. You have oil pressure the switch closes gives a path to ground and your “gauge” points to the middle and you feel all warm and fuzzy

Digital gauges, or clusters with dummy lights(97) are the opposite with normally closed switches so the circuit grounds with low to now oil pressure to illuminate the light, with proper oil pressure it opens to turn it off.

Why am I explaining how these work? Because the level switch works the same way as the latter - low oil LEVEL the switch is closed and the message center will tell you to “fill your oil, dummy!”….which means plugging it in directly to the gauge works the opposite of how I want. Damn…

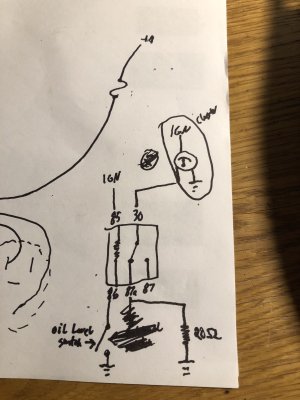

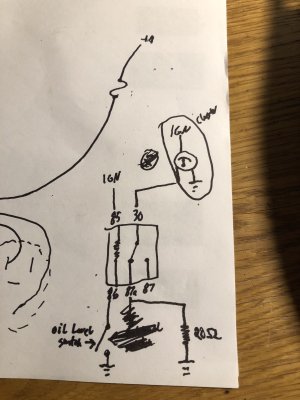

But then I had a vision, a vision of this!

This is what makes oil level sensing through an analog gauge possible!

So here’s what I whipped up

My expertly drafted diagram basically explains it. I actually made a mistake initially deleting the resistor jumper but in this circuit I need both a full current circuit the jumper originally in place for the pressure sender provided, but ALSO the resistor itself but in a different place in my added wiring to ground through the volt gauge - terminal.

The other thing is the modification to my slosh module… I actually forgot what exactly I did here because I did it years ago to stop the check gauges light from triggering from the oil sender but it is necessary for this mod as well since it’s expecting to see voltage through the signal circuit when running, which it isn’t.

Anyway, here is a quick clip in action with me manually shorting it to ground(you can hear the relay click)

The only sucky part is I had kind of hoped the oil temperature sensor part of the mark VIII switch would work for the temperature gauge(it once again doesn’t say *which* temperature!

) but it ohms our way way higher than the gauge sender unfortunately, closer to the ECT sensor.