Okay, here are the long awaited tips.

1. Before you can assemble the two parts together, the steering assembly and the tilt wheel assembly, including the cylinder lock, you have to place something under the tilt wheel arms. I placed the tilt wheel arms (that press the tilt assembly up when released and restrict the down motion) in a vice, not clamped, but enough pressure to press them down or open, depending on how you are looking at the unit. Then place a ball bearing or something you can remove when you finally tilt the wheel up, will drop out.

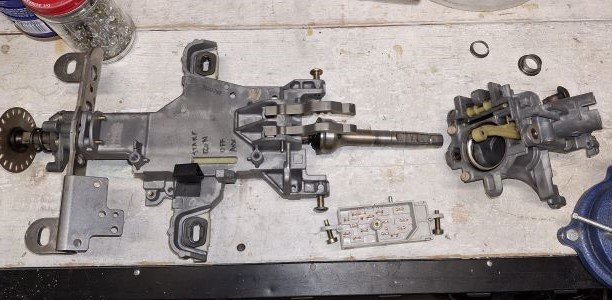

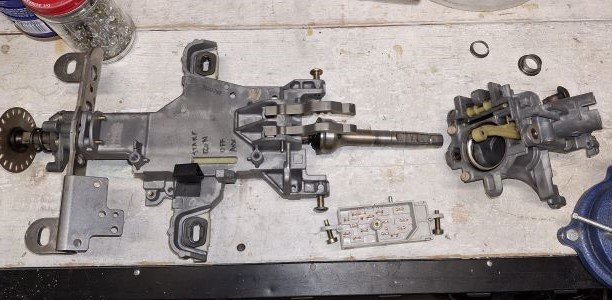

2. Put the assemblies loosely together, steering assembly that mounts to the dash and the tilt assembly. This includes the steering shaft, locking cylinder lock assembly and ignition switch. Make sure to install the locking cylinder gear and assembly in a the RUN position. Make sure the ignition switch is in the run position as well when mounting it to the steering assembly.

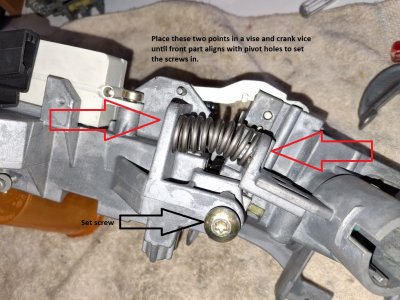

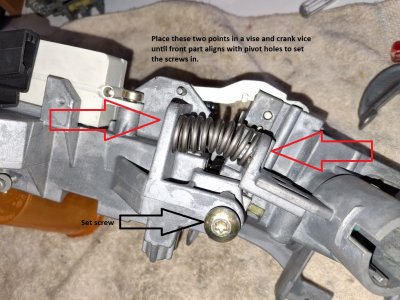

3. Place the tilt spring between the two parts at its mounting hole and mounting pin. Place the two parts as show in the pic below in a vice and slowly tighten the vice until the tilt assembly mounting holes align with the mounting pins and tighten the mounting pins (screws) into the mounting holes.

Done! I highly recommend doing this a few times to get it down so you don't 1. Forget any parts, 2. understand how the to parts work together.

I need to take it apart again and see if I really need the part I ordered. Supposed to be here tomorrow. I got my white lithium grease and need to lube everything up again when I do a final assembly.

I learned a lot from doing this. The tilt wheel assembly is no longer a mystery and I understand the ignition system much better now.

I think the original problem is going to boil down to a bad ignition switch. The white box on the bottom of the steering assembly. I looked all over my sheds and garage for the OEM ignition box and never found it. Guess I shit-canned it a while back when I was cleaning out the garage.